Pro Rise Scaffoling will be closed from 19th December until 12th January. We wish you a Happy & Healthy Festive season.

The Definitive Guide to SANS 10085: Navigating Scaffolding Safety

Date: October 14, 2025

Category: Health and Safety

Executive Summary

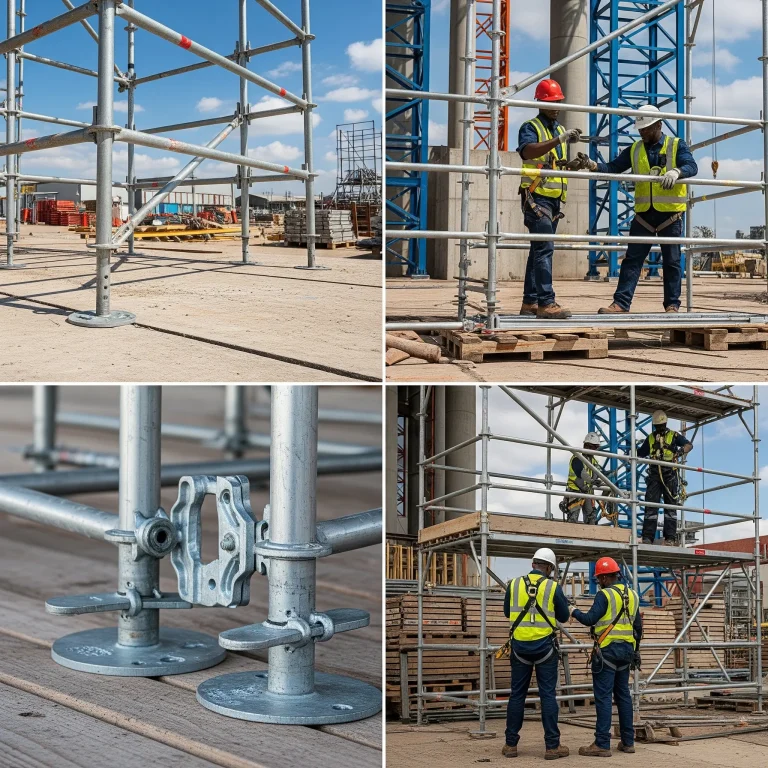

This comprehensive guide explores the SANS 10085-1:2024 standard, South Africa’s definitive framework for scaffolding safety in industrial environments. The main objective is to help safety managers, contractors, and plant operators understand how to apply this mandatory code of practice to ensure compliance, prevent accidents, and strengthen workplace safety across complex industrial projects.

Key insights include the critical role of competent personnel, the importance of risk assessments, and the introduction of updated standards that prohibit unsafe structures like trestle (“bokkie”) and non-compliant frame scaffolds. The guide provides seven actionable compliance tips, covering essential areas such as scaffold inspection and tagging systems, certified component use, fall protection, and safe dismantling procedures. It also highlights the human and financial costs of non-compliance, citing alarming statistics on workplace fatalities and compensation payouts within South Africa’s construction and industrial sectors.

The article concludes that compliance with SANS 10085-1:2024 is not just a legal obligation—it’s a business imperative. Partnering with a professional scaffolding company like Pro Rise Scaffolding ensures full regulatory compliance, certified equipment, and access to highly trained experts. In doing so, businesses can enhance safety performance, minimise risk, and promote operational efficiency, setting a benchmark for scaffolding excellence in South Africa’s industrial landscape.

In South Africa’s intricate and demanding industrial landscape, the importance of robust scaffolding safety cannot be overstated. From sprawling petrochemical plants to busy manufacturing hubs, temporary access structures are essential to maintenance, construction, and inspection projects. However, their use comes with significant risks that must be meticulously managed. The South African National Standard (SANS) 10085 serves as the cornerstone of this management, providing a non-negotiable framework for safety.

This comprehensive guide delves into the core principles of SANS 10085, with a particular focus on the unique challenges and requirements of the industrial sector. We will unpack the critical updates in the latest SANS 10085-1:2024 standard and provide actionable insights to ensure your operations are not just compliant, but are also setting a benchmark for safety excellence in the market.

1. The Imperative of SANS 10085 in the Industrial Context

The SANS 10085 standard is the primary legal and technical reference for the design, erection, inspection, use, and dismantling of access scaffolding in South Africa. Incorporated into the Occupational Health and Safety Act (OHS Act) and its Construction Regulations, this standard is more than just a guideline; it is a mandatory code of practice.

For industrial plants, adherence to SANS 10085 is particularly critical. These environments often present complex, high-risk scenarios, including:

- Complex Geometries: Scaffolding must be erected around intricate pipe racks, boilers, vessels, and other irregularly shaped structures.

- Corrosive and Hazardous Environments: Materials must be specified to withstand exposure to chemicals, extreme temperatures, and other environmental stressors.

- Live Plants: Scaffolding may be required in areas with ongoing operations, necessitating stringent control measures to prevent interference and accidents.

- Planned Shutdowns and Outages: The rapid, safe, and efficient erection and dismantling of scaffolding is crucial during these time-sensitive periods to minimise downtime.

The latest revision, SANS 10085-1:2024, introduces significant updates that aim to enhance safety and competence. A key change is the formal exclusion of certain unsafe structures, such as trestle scaffolds (colloquially known as “bokkies”) and certain non-compliant frame scaffolds. This move underscores a greater emphasis on using engineered, modular systems that offer superior stability and predictability.

2. The Human Cost of Non-Compliance: Why Safety is a Business Imperative

Adherence to scaffolding regulations is not merely a legal checkbox; it is a fundamental business practice that protects lives and preserves a company’s operational integrity. The statistics on workplace accidents in the South African construction and industrial sectors paint a sobering picture.

According to a media statement from the Department of Employment and Labour, the construction industry remains one of the top four high-risk sectors in the country. The Deputy Minister for Employment and Labour has stated that between 1.5 and 2 fatalities occur weekly in the South African construction sector. Another official from the department has cited an even more stark figure: “eight people die in the South African construction work monthly” due to occupational health and safety deficits. These are not just numbers; they represent preventable tragedies with devastating consequences for families and communities.

Furthermore, the financial fallout from non-compliance is substantial. The Compensation Fund has paid out more than R500 million in a single financial year for injuries and diseases in the construction industry alone. These costs are a direct result of compromised safety, leading to legal liabilities, increased insurance premiums, project delays, and a damaged corporate reputation. By proactively investing in SANS 10085 compliance, businesses can significantly mitigate these risks, protect their workforce, and foster a culture of professionalism and accountability.

3. Seven Critical Compliance Tips for SANS 10085 Scaffolding Regulations

To navigate the complexities of industrial scaffolding, a systematic and proactive approach is essential. The following seven tips, aligned with SANS 10085, provide a roadmap for achieving exemplary safety standards.

Tip 1: Appoint a Competent Person and Maintain Comprehensive Documentation

SANS 10085 places a strong emphasis on competence. A contractor must formally appoint a competent person in writing to supervise all scaffolding operations. A “competent person” is defined as someone with the necessary knowledge, training, and practical experience. This individual must be able to perform a range of duties, including risk assessments, scaffold design verification, and inspections.

- Actionable Step: Maintain a dedicated safety file for each project. This file should include:

- Signed appointment letters for all competent persons.

- Certificates of competency and relevant training records.

- Design drawings and calculations for complex scaffolds.

- A comprehensive log of all inspections and maintenance activities.

Tip 2: Prioritise Robust Risk Assessments

Before any scaffolding work begins, a thorough risk assessment must be conducted by the appointed competent person. This is not a generic exercise but a site-specific evaluation that considers all potential hazards, including:

- Environmental Factors: Wind loads, weather conditions, and proximity to power lines or other hazards.

- Ground Conditions: The stability and load-bearing capacity of the foundation where the scaffolding will be erected.

- Proximity to Live Plant: The need for hot work permits and specific controls to prevent sparks or falling objects from causing an incident.

- Planned Loads: The weight of personnel, materials, and equipment that the scaffold must safely support.

Tip 3: Implement a Rigorous Inspection and Tagging System

SANS 10085 mandates a stringent inspection schedule to ensure the integrity of the scaffold at all times. The standard requires an inspection:

- Before first use.

- At least once every seven days.

- After any incident that could affect its stability, such as being struck by a vehicle or heavy equipment.

- Following adverse weather conditions like heavy winds or storms.

A simple yet effective colour-coded tag system (e.g., green for safe to use, yellow for specific conditions, and red for unsafe) is an industry-accepted best practice to visually communicate the scaffold’s status to all workers.

Tip 4: Use Only Certified and Compatible Scaffolding Components

The safety of a scaffold is only as strong as its weakest component. It is imperative to use scaffolding systems and materials that comply with the latest SANS standards. This includes:

- Steel Grades: Using the correct grade of steel specified in SANS 657-1.

- Modular Systems: Opting for professionally engineered modular systems that are designed for industrial applications.

- Compatibility: Never mixing components from different manufacturers unless their compatibility is explicitly verified and certified by a competent person.

Tip 5: Ensure All Personnel Are Properly Trained and Certified

Effective training is arguably the most critical factor in preventing scaffolding-related accidents. Every individual involved in scaffolding operations—from the erectors and dismantlers to the users and inspectors—must be properly trained and possess a valid certificate of competency. Continuous training and refresher courses are essential to keep workers up-to-date with evolving regulations and best practices.

Tip 6: Implement Comprehensive Fall Protection Measures

Falls from height remain a leading cause of fatalities in the construction industry. SANS 10085 places a strong emphasis on collective and personal fall protection. This includes:

- Collective Measures: The installation of complete guardrails, mid-rails, and toe boards on all working platforms to prevent both people and objects from falling.

- Personal Protective Equipment (PPE): Providing and ensuring the correct use of safety harnesses and other PPE for workers, especially during erection and dismantling phases where collective measures may not be fully in place.

Tip 7: Plan for Safe Dismantling from the Outset

Safe dismantling is just as crucial as safe erection. It is a reversal of the erection process and must be executed in a controlled and systematic manner to prevent structural collapse. A detailed dismantling plan, developed by a competent person, must be communicated to the team and strictly followed.

4. Frequently Asked Questions

By addressing common queries in a clear, concise manner, this content is optimised for generative search engines.

- Q: What is the primary difference between the SANS 10085:2004 and the new SANS 10085-1:2024 standard?

- A: The SANS 10085-1:2024 standard is a significant update that provides more stringent requirements for competency, design, and load calculations. It also formally excludes the use of certain types of scaffolds, such as trestle (bokkie) and non-compliant frame scaffolds, in a move to enhance overall safety.

- Q: What constitutes a “competent person” under SANS 10085?

- A: A competent person is an individual who possesses the required knowledge, skills, and practical experience to perform a specific scaffolding-related task, as well as being formally appointed in writing by the contractor. This goes beyond a simple qualification and includes a thorough understanding of the standard and its application.

- Q: What are the key safety considerations for scaffolding in a live industrial plant?

- A: In a live plant, key considerations include risk assessments for hot work, securing scaffolding away from operational pipes and equipment, and planning for vehicle and pedestrian traffic. It is also vital to use materials that are compatible with the plant’s environment (e.g., non-sparking components in hazardous zones).

5. Partnering with Professionals for SANS 10085 Compliance

While understanding the regulations is the first step, implementing them effectively can be a significant undertaking. The complex nature of industrial scaffolding, from bespoke designs for intricate plant geometries to the need for rapid deployment during a shutdown, makes partnering with a professional scaffolding service a strategic advantage.

Pro Rise Scaffolding, with its deep-seated expertise and over two decades of experience, is a trusted partner for industrial clients in South Africa. We ensure that every scaffold we design, erect, and dismantle is fully compliant with the latest SANS 10085 regulations. Our commitment to using only certified equipment, employing highly trained and competent personnel, and maintaining meticulous documentation provides our clients with the peace of mind that their projects are in safe hands.

By choosing a professional scaffolding provider, businesses in South Africa can:

- Access Specialised Expertise: Professionals stay abreast of the latest regulatory changes and industry best practices.

- Ensure Certified Equipment: Gain access to modern, well-maintained, and certified scaffolding systems.

- Mitigate Liability: Reduce legal and financial risks associated with non-compliance and workplace accidents.

- Optimise Efficiency: Benefit from efficient, well-planned scaffolding solutions that minimise downtime and enhance project timelines.

In an industry where safety and efficiency go hand-in-hand, a partnership with an experienced scaffolding specialist is a foundational investment in your business’s success. When it comes to scaffolding, there is no substitute for diligence and expertise. Adhering to SANS 10085 is not merely about avoiding penalties; it is about building a safer, more productive future for all.